|

Smaller scale manufacturing operations (1,000-5,000 SF) seem to be opening up shop and gaining momentum faster than ever. Why is this happening? I think the cost of manufacturing machines has come down and because of the strong economy, entrepreneurs have the spirit and the capital to start a manufacturing operation or grow their business with existing cash or lines of credit. Also, the cost of distribution continues to become more competitive. Another crucial factor that has contributed to the success of smaller scale manufacturing businesses is social media and the internet. 20 years ago, more capital was needed to advertise a product in magazines, newspapers, TV, radio, etc. Today a manufacturing business can create an Instagram page, Facebook page, and a website for less than $15 per month and reach the entire world! https://www.nelsonprecisionmfg.com/, https://www.thesuperchargerstore.com/, and http://gorillasplitters.com/ are perfect examples of successful Tucson businesses that sell their products across the world through social media and website efforts (paid advertising sometimes isn’t even a necessity). Is there anything that can help our manufacturing companies continue to grow and prosper? Yes, decreased regulations is one of the most important factors and I’m not talking about environmental regulations. Contrary to popular belief, modern day manufacturing operations are very clean and very rarely involve exhaust. For example, I visited two business owners within the past month who have automotive related businesses. One repairs and sells transmission parts and the other repairs and sells electrical parts for vehicles. Because of government regulations, lots of replacement parts cannot be manufactured at a price that would make sense for the consumer or manufactured at all. Decreased regulations would spark an increase manufacturing while creating more affordable products for consumers. For example, if you have an electrical issue with your 20 year old Ford F-150 that needs a replacement part, you wouldn’t have to search for an existing part in a junk yard or buy one on Ebay for $300 when a manufacturing company can manufacture that part for $5 and sell it to the market for $15. Decreasing regulations effectively creates more supply which creates more industry and more affordable parts for the average Joe. We can also support Pima College and their efforts to expand their already successful trades and manufacturing programs. There is a big demand for manufacturing workers and these jobs pay well because of the specific skill set, strong demand, and lack of supply. A manufacturing employee can learn a skill set at Pima College for a fraction of the cost of a University degree and in just a few years. Then that student can step into the workforce making $40,000 + with limited college debt and room to climb the ladder. Sometimes a manufacturing company will even help their new employee pay off their student loan debt. Recent announcements with the South 32 mine in Patagonia and Rosemont Copper are bringing increased activity to Tucson with companies such as Hexagon Mining and Caterpillar. We expect to see this activity ramp up and soon we will see increased activity with Rosemont and South 32 sub-contractors and materials suppliers, especially in the Palo Verde to Vail sub markets. Aerospace, defense and mining manufacturing continue to lead the charge in manufacturing. The strongest sub-markets in Tucson are the Northwest and Downtown markets. As the downtown and northwest markets have around 3% vacancy we will watch as demand grows further North into Marana with new construction and further south towards the airport and Vail, effectively filling already vacant buildings to the South and East. Airport and Palo Verde area activity is much stronger than this time last year. Rates in the Palo Verde market have already jumped from $.50 MG to $.60 MG within one year. Tucson continued to experience full employment, ending February at a 4.5% unemployment rate and adding 5,400 jobs over the past year. Meanwhile, manufacturing employers struggle to find skilled manufacturing labor. Market Moves -Raytheon announced a merger with United Technologies which will be the largest defense merger in US history -Nikola Motors announced a new 400 acre manufacturing facility in Pinal County -Modular Mining expands autonomous mining research, development and manufacturing operations in Tucson -Lucid Motors announces new $700,000,000 manufacturing facility in Pinal County -Harsch Investment started construction on a 150,000 SF + speculative distribution facility near the Tucson Airport Most recent manufacturing deals completed by Max Fisher; Thesuperchargerstore.com Arizona Heritage Cabinetry Steel Dor Paperwork Analysis Gorilla Splitters Nelson Precision Machining Boogeyman Customs Photonic Materials Delta Development Helico Solar HDPE Fusion Photos are from the Pima College trades college

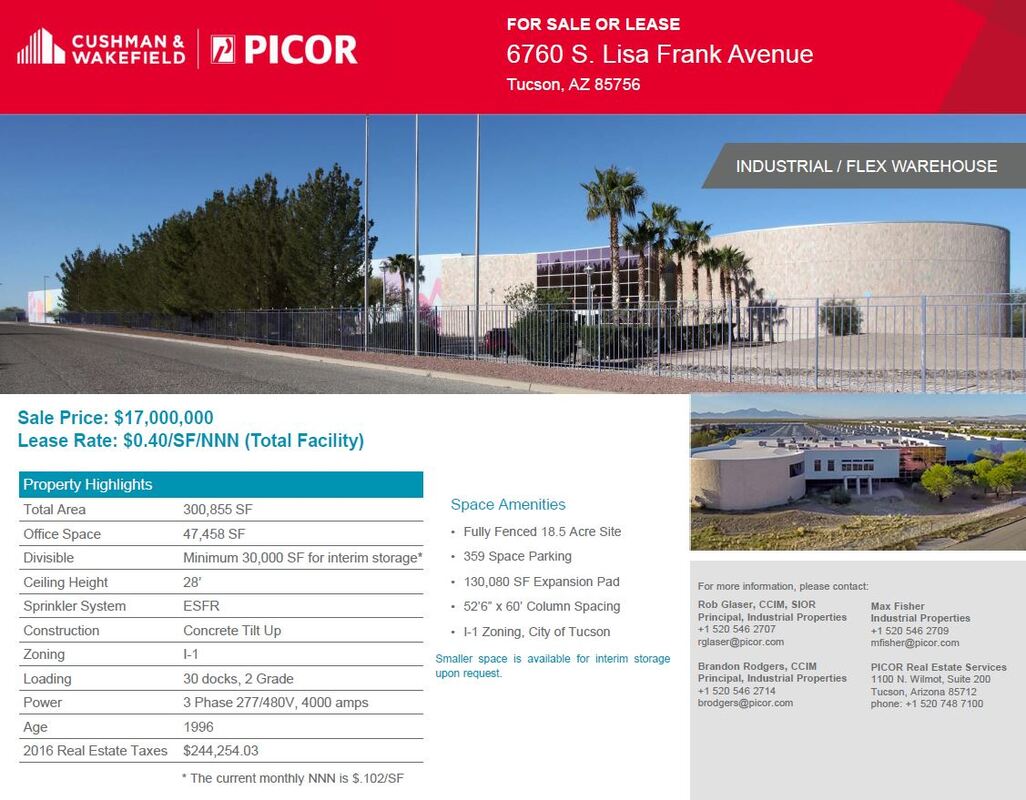

Featured Tucson Manufacturing Facility listed by Rob Glaser, Brandon Rodgers, and Max Fisher of Cushman & Wakefield | PICOR

0 Comments

Leave a Reply. |

AuthorMax Fisher, Industrial Properties Broker Archives

April 2024

Categories |

RSS Feed

RSS Feed